Research team uses 3D printers to create microfluidic probes

For about a decade, scientists have struggled to find an inexpensive, practical alternative to microfluidic probes. Following an experiment by a New York University research team, a new avenue may available to researchers.

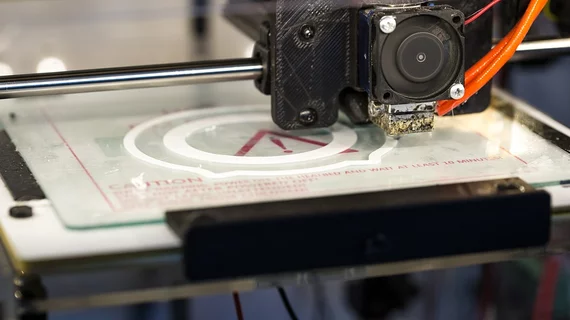

An NYU Abu Dhabi research team recently used a 3D printer to create a “functional, integrated and inexpensive” microfluidic probe that can study cancer cells and living organisms in a petri dish, according to a study published in Scientific Reports - Nature.

Microfluidic probes are described as tiny, scientific tools—about the size of a pen tip—and are used to study, process and manipulate live cell cultures in a controlled environment. They are usually made out of glass or silicone.

Though microfluidic probes were invented about a decade ago, new types are still being developed and perfected today. The tools have received criticism because they are difficult to produce on demand and are relatively expensive to make in large quantities, according a related press release.

However, microfluidic probes also have a lot things working in their favor.

“The main advantage of the ]microfluidic probe] is that it overcomes major limitations of conventional channel-based microfluidics, such as high shear stress and tiny patterning areas, while allowing localized delivery of reagents for biological applications,” the study said. “Another major advantage of the [probe] is its ability to pattern large, open planar surfaces using conventional lab equipment.”

Mohammad Qasaimeh, an NYU Abu Dhabi assistant professor of mechanical and biomedical engineering, said in the release “3D printers provide a simple rapid and low-cost technique for fabricating (microfluidic probes).”

“It’s cheaper to produce, easy to scale up and fast to fabricate—all steps, from design to product, can be made in less than a day,” he said, and as a result, “any science lab with a moderate resolution stereolithography printer will be able to fabricate 3D [probes] on demand and use them to process cells reliably.”

During the study, the research team used two independent microfluidic probe designs, printers and setups to fabricate different types of microfluidic probes. According to the study, both designs featured cylindrical tips and conical necks, while they differed in in their world-to-chip interface.

“Results show that, for most (microfluidic probe) applications, printer resolution artifacts have negligible impact on probe operation, reagent pattern formation and cell staining results,” the study said. “Thus, any research group with a moderate resolution stereolithography printer will be able to fabricate the (microfluidic probe) and use them for processing cells or generating microfluidic concentration gradients.”